R&D Centers

Our company has a professional core R&D production team and an advanced independent R&D laboratory. With independent core technology, strict selection of raw materials, rigorous lean production, stable and reliable quality, and professional and considerate services, we provide customers with bonding and sealing solutions and technical support.

Characteristic

-

1. Non Corrosive To Metals, In Accordance With MIL-A-461468 Corrosion Test Standard

-

2. Room Temperature Vulcanizable

-

3. Extremely Low Odor

-

4. Adhesive With Multiple Substrates Without The Need For Primer

-

5. Excellent Heat Resistance, Ozone Resistance, And Chemical Erosion Resistance

-

6. Excellent Electrical Insulation Performance

-

7. Single Component System Is Simple And Convenient To Use

Application

Sealant can replace imported oil resistant sealant and is used as a matching adhesive for all automobile manufacturers, agricultural vehicle factories, forklift factories, diesel engine factories, shipyards, and other manufacturers. Can be used for sealing oil, gas, and water in power, chemical, mechanical, transmission, oil tank, oil pan, cork pad, front and rear axles, front and rear end caps, etc. It is also suitable for detachable sealing of joint surfaces or flanges related to engines, water pumps, valves, gearboxes, reducers, etc. in automobiles, motorcycles, etc., and can also be used for detachable thread sealing.

This adhesive has strong filling ability, aging resistance, and surface curing time of less than 20 minutes. In addition, the structure of organic silicon products contains both "organic groups" and "inorganic structures". This special composition and molecular structure combine the characteristics of organic matter with the functions of inorganic matter, and have many excellent properties such as high and low temperature resistance, weather aging resistance, electrical insulation, odor resistance, hydrophobicity, flame retardancy, non-toxic, non corrosive, and physiological inertness. Some varieties also have oil resistance, solvent resistance, and radiation resistance.

Compared with other polymer materials, the most outstanding performance of silicone products is:

Excellent temperature resistance, dielectric properties, weather resistance, physiological inertness, and low surface tension;

Excellent temperature resistance, dielectric properties, weather resistance, physiological inertness, and low surface tension;

Excellent temperature resistance, dielectric properties, weather resistance, physiological inertness, and low surface tension;

Excellent temperature resistance, dielectric properties, weather resistance, physiological inertness, and low surface tension;

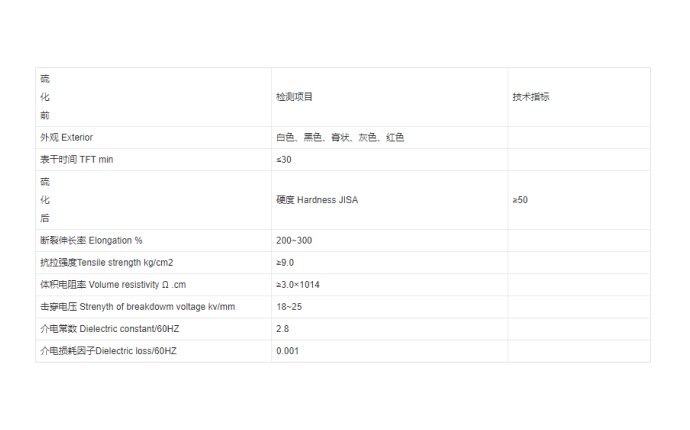

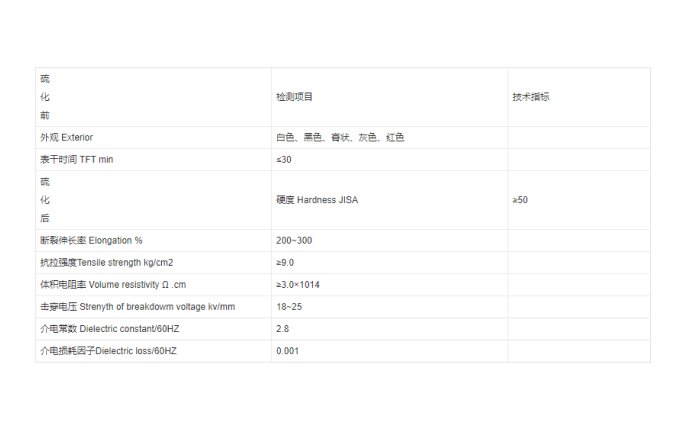

Technical Characteristics

Usage

01

Step 1

Use a degreased cotton soaked in acetone or gasoline to remove oil stains on the sealing joint surface, and let it dry at 15 ℃~30 ℃ for 15-30 minutes for later use.

02

Step 2

Evenly extrude according to the size of the joint surface and gap, and the appropriate amount of coating should be slightly extruding a rubber ring after the joint surface is combined. threads inside the hole can be coated with a paintbrush.

03

Step 3

After coating the liquid sealing gasket on the bonding surface, quickly assemble and tighten it, and the time interval from glue adjustment to assembly should be controlled within 0.5 hours.

04

Step 4

The combined components can only enter the next process after being vulcanized at 23 ± 2 ℃ for 12 hours. The component withstand voltage test should be conducted after 24 hours of vulcanization.

05

Step 5

After vulcanization, the liquid sealing gasket remaining on the bonding surface can be removed with a sharp knife to remove the adhesive film that has leaked to the outside of the bonding surface, but it is not allowed to forcefully tear it by hand. You can also wipe it off with cotton yarn soaked in gasoline.

06

Step 6

When disassembling, a wooden mallet can be used to strike the joint surface along the side. If it becomes loose, the adhesive on the joint surface can be scraped off with a copper scraper or wiped off with cotton yarn soaked in gasoline.

Package And Storage

This Product Is Packaged In 100ml Metal Hose Or 310ml Plastic Cylinder.

This Product Is Packaged In 100ml Metal Hose Or 310ml Plastic Cylinder.

This Product Is Packaged In 100ml Metal Hose Or 310ml Plastic Cylinder.

This Product Is Packaged In 100ml Metal Hose Or 310ml Plastic Cylinder.